By knowing the exact cost of production, manufacturers can also identify areas where they can reduce costs and increase profitability. Process costing can be a useful tool for companies to track their costs and make sure that they are making products efficiently. Costs for each stage are summed together and then divided by the total number of items produced. It is important to include partially completed items when determining the cost per unit as this will give a more accurate representation of the true cost. The main benefit of Process Costing is that it provides information that can be used to make critical business decisions. For example, managers using this system can assess profit margin by product and isolate problem products before they become major issues.

7 Ways Technology Can Help Restaurants Decrease COGS and … – Restaurant Technology News

7 Ways Technology Can Help Restaurants Decrease COGS and ….

Posted: Thu, 29 Jun 2023 01:04:22 GMT [source]

For example, paint ingredients would be direct materials as they are materials needed to make a company’s products. Conversion costs are the indirect costs incurred in converting direct materials into finished products, such as factory overhead. Cost drivers are the factors that cause changes in the total cost of producing a good or service.

Importance of Process Costing

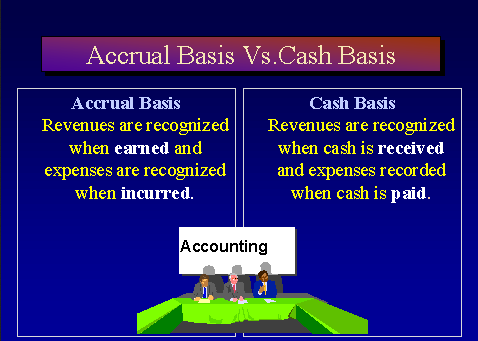

After the expense per unit for each process is calculated, the results can be added together to obtain a total cost per unit. The result will be a dollar amount that can be used by the manufacturing company to set prices and determine if the products are producing a profit. While both systems produce a cost of goods sold for a given period, Process Costing focuses on the product’s progression through various stages of production. Job-order costing focuses on a specific product or service produced for a given customer.

Business owners use process costing because it creates a flexible production process. Companies needing to refine their process can simply add or remove a process as necessary. Business owners typically look for ways to refine a production process to increase cost savings. Adding a process allows companies to produce slightly different goods or improve product quality.

Integration with other Systems

This is the case for plumbers, mechanics, freelancers, movers, and anyone who works in a trade or provides customers an estimate before doing any work. Just in time (JIT) inventory management systems have been widely used in the automotive manufacturing and assembly industry, as well as others. The idea is to have parts arrive at the assembly plant just in time to go into the production line when they are needed. Let’s say at the end of a day, two bikes are half completed, and have accumulated $25 in costs each.

Process costing allocates costs to each production unit based on a predetermined overhead rate. This rate is determined by dividing the total overhead costs by the total number of units produced. In job costing, costs are allocated to each job or project based on the costs incurred. The main advantage of using a process costing system is that it provides managers with information they can use to improve the efficiency of the production process.

Cost of Raw Materials

Process costing is optimal when the costs cannot be traced directly to the job. For example, it would be impossible for David and William to trace the exact amount of eggs in each chocolate chip cookie. It is also impossible to trace the exact amount of hickory in a drumstick.

Process costs represent a higher level of accuracy than job-order costing, but they are also more complex and time consuming to develop. Using process costing, a seltzer bottling company would assign costs to each stage in the bottling process. It then totals the costs from each stage over an accounting period, dividing the overall process cost by the number of finished bottles to obtain a cost per bottle.

Costing Multiple Products

However, specific cars have custom options, so each individual car costs the sum of the specific parts used. When the units are completed, they are transferred to finished goods inventory and become costs of goods sold when the product is sold. Understanding the company’s organization is an important first step in any costing system. The sticks are dried, and then sent to the packaging department, where the sticks are embossed with the Rock City Percussion logo, inspected, paired, packaged, and shipped to retail outlets such as Guitar Center. Process costing provides a more accurate estimate of each unit’s production cost since the costs are allocated based on a predetermined rate.

What are the 7 types of cost?

The types of costs evaluated in cost accounting include variable costs, fixed costs, direct costs, indirect costs, operating costs, opportunity costs, sunk costs, and controllable costs.

A mistake in cost estimation in one process will have an impact on cost estimation in the following processes, the price of work-in-progress, and the price of finished goods. Establishing a meaningful system for allocating joint production costs between departments can be complex and expensive, depending on how many processes what are the three types of accounts are involved. It can also lead to errors if the cost allocation process is incorrectly done. Since the costs are averaged, assessing the profitability of individual products or process stages is difficult. It can make it difficult for management to determine which product lines or processes should be eliminated if needed.

What are examples of process costing companies?

Examples of companies that use process costing include Chevron Corporation (petroleum products), the Wrigley Company (chewing gum), and Pittsburgh Paints (paint).